The modern manufacturing landscape demands precision, efficiency, and innovation at every turn. As industries push the boundaries of what’s possible, the need for sophisticated plastic molding solutions has never been more critical. Enter Repmold, a pioneering force in advanced plastic molding technology that’s reshaping how industries approach their most complex manufacturing challenges.

With decades of expertise and a commitment to cutting-edge innovation, Repmold stands at the forefront of the plastic molding revolution. From automotive giants seeking lightweight solutions to healthcare companies requiring biocompatible components, Repmold’s advanced molding technologies deliver the precision, quality, and scalability that today’s industries demand.

The Evolution of Plastic Molding Technology

Traditional plastic molding has undergone a remarkable transformation. What once relied on basic injection techniques now encompasses sophisticated processes that can create components with tolerances measured in microns. This evolution has opened doors to applications previously thought impossible, from intricate medical devices to high-performance automotive parts.

Modern plastic molding combines advanced materials science with precision engineering. Today’s processes can handle everything from biodegradable polymers to high-strength engineering plastics. The result is a manufacturing capability that can meet the most demanding specifications while maintaining cost-effectiveness at scale.

The industry has also embraced automation and smart manufacturing principles. Computer-controlled systems now monitor every aspect of the molding process, from temperature and pressure to cycle times and part quality. This level of control ensures consistency and repeatability that manual processes simply cannot match.

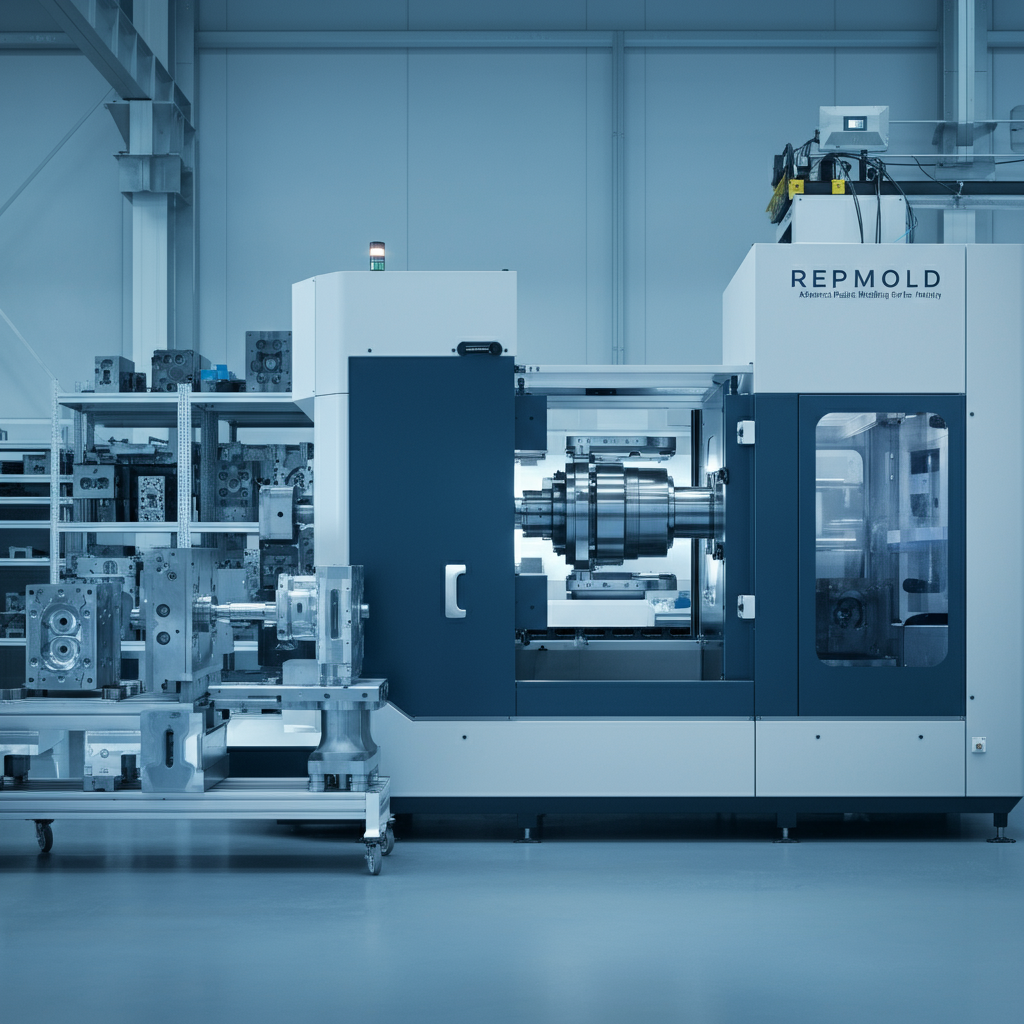

Repmold’s Innovative Approach to Plastic Molding

Repmold has built its reputation on pushing the boundaries of what’s possible in plastic molding. Their approach combines state-of-the-art equipment with proprietary processes that deliver superior results across a wide range of applications.

The company’s multi-shot molding capabilities represent a significant advancement in the field. This technology allows for the creation of complex parts with multiple materials or colors in a single molding cycle. The result is components that would otherwise require assembly, reducing manufacturing time and improving part integrity.

Repmold’s micro-molding expertise addresses the growing demand for miniaturized components. Using specialized equipment and techniques, they can produce parts with features as small as 0.1mm while maintaining tight tolerances. This capability is particularly valuable in electronics and medical device manufacturing.

Their overmolding technology creates strong bonds between different materials, enabling the production of parts with varying properties in different zones. This approach is ideal for creating ergonomic grips, seals, and gaskets that require both rigid structural elements and flexible contact surfaces.

Cutting-Edge Technologies and Capabilities

Repmold’s technology portfolio encompasses the full spectrum of advanced molding processes. Their insert molding capability allows for the encapsulation of metal components, electronic elements, or other materials within plastic parts. This process creates integrated assemblies that reduce part count and assembly time while improving reliability.

The company’s gas-assisted injection molding technology produces hollow parts with excellent structural properties while using less material. This approach is particularly valuable for creating lightweight components without sacrificing strength or durability.

Repmold’s clean room molding facilities meet stringent contamination control requirements for medical and pharmaceutical applications. These controlled environments ensure that sensitive components meet the highest purity standards required for implantable devices and drug delivery systems.

Their rapid prototyping capabilities accelerate product development cycles. Using advanced 3D printing and soft tooling techniques, Repmold can produce prototype parts in days rather than weeks, allowing clients to test and refine their designs quickly.

Industry Applications and Impact

Automotive Excellence

The automotive industry has embraced Repmold’s advanced molding solutions for applications ranging from interior components to under-the-hood parts. Their lightweight molding techniques help manufacturers meet increasingly stringent fuel efficiency standards while maintaining safety and performance requirements.

Repmold’s expertise in creating complex geometries has enabled the production of integrated dashboard assemblies that combine multiple functions in single parts. This approach reduces weight, assembly time, and potential failure points while improving overall vehicle quality.

Their work with engineering plastics has produced components that can withstand extreme temperatures and harsh environments. From engine compartment parts that resist chemicals and heat to exterior trim pieces that maintain their appearance after years of UV exposure, Repmold’s solutions deliver long-term reliability.

Healthcare Innovation

The healthcare sector presents unique challenges that Repmold addresses with specialized solutions. Their biocompatible molding processes ensure that medical devices meet strict regulatory requirements while delivering the performance that healthcare professionals demand.

Repmold’s micro-molding capabilities have enabled the production of intricate drug delivery devices with precise dosing mechanisms. These components require tolerances that push the limits of manufacturing precision, yet they must be produced at volumes that make them economically viable.

Their work in creating disposable medical devices has helped healthcare providers improve patient safety while managing costs. From syringes to surgical instruments, Repmold’s processes ensure consistent quality while meeting the demanding timelines of healthcare manufacturing.

Consumer Goods Innovation

Consumer goods manufacturers rely on Repmold’s expertise to create products that combine functionality with aesthetic appeal. Their multi-material molding capabilities enable the creation of products with premium feel and appearance that stand out in competitive markets.

The company’s work with sustainable materials addresses growing consumer demand for environmentally responsible products. Their processes can handle recycled content and biodegradable materials without compromising quality or performance.

Repmold’s ability to create complex textures and finishes directly in the molding process eliminates secondary operations while delivering superior surface quality. This capability is particularly valuable for consumer electronics and household appliances where appearance is critical.

Quality Assurance and Industry Standards

Repmold’s commitment to quality extends beyond advanced equipment to comprehensive quality management systems. Their facilities maintain ISO certifications and adhere to industry-specific standards that ensure consistent, reliable results.

Their quality control processes include advanced inspection technologies that can detect defects at the microscopic level. Statistical process control methods monitor every aspect of production, enabling real-time adjustments that maintain quality while minimizing waste.

The company’s traceability systems track every component from raw material receipt through final delivery. This capability is essential for industries with strict regulatory requirements and provides valuable data for continuous improvement efforts.

Future-Focused Manufacturing Solutions

Repmold continues to invest in next-generation technologies that will define the future of plastic molding. Their research and development efforts focus on sustainable manufacturing processes, advanced materials, and smart manufacturing integration.

The company’s work with Industry 4.0 technologies promises to further enhance their manufacturing capabilities. Connected systems that share data across the production process enable predictive maintenance, optimized cycle times, and improved quality control.

Repmold’s leadership in advanced plastic molding solutions positions them as the partner of choice for industries seeking to push the boundaries of what’s possible. Their combination of cutting-edge technology, proven expertise, and unwavering commitment to quality makes them an invaluable resource for manufacturers across diverse sectors.

Through continuous innovation and a deep understanding of their clients’ needs, Repmold remains at the forefront of the plastic molding industry, delivering solutions that not only meet today’s challenges but anticipate tomorrow’s opportunities.